Chery-backed company starts solid-state battery production

A Chinese company with backing from automaker Chery has produced its first batch of solid-state batteries, a technology long promised as the key to unlocking the full potential of electric cars. The industry has been flooded with claims and predictions, but this development seems to be a tangible step from laboratory theory to factory production.

The company at the center of this development is Anhui Anwa New Energy Technology. Established in June 2020, Anwa is not an isolated startup. Automotive giant Chery New Energy holds a nearly 10% stake in the company, with another 5.89% owned by the well-known battery manufacturer Gotion High-Tech.

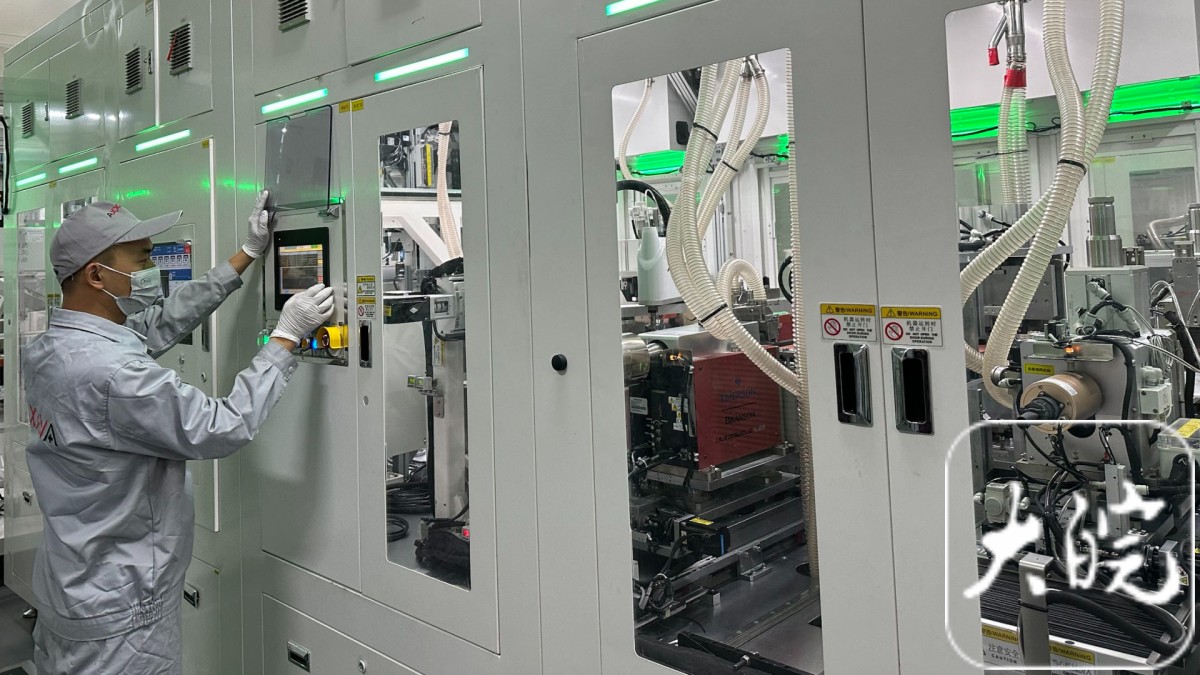

On July 4, Anwa announced that the first engineering samples of its solid-state batteries had rolled off a new production line in Wuhu, China. These are not yet batteries for the mass market but are crucial prototypes for testing and validation. The first-generation battery boasts an energy density of 300 Wh/kg.

This is a significant improvement in how much energy can be stored in a given weight, a key factor for extending the driving range of electric cars without adding cumbersome weight. Anwa officials also stated the batteries have passed a stringent new safety standard referred to as "No Fire No Explosion," directly addressing one of the major concerns associated with current lithium-ion battery technology.

The production facility itself points to Anwa's serious ambitions. The production line is designed for what the company calls a "full-chain" process. It uses a 5-step dry manufacturing technique, which is claimed to reduce energy consumption by 20% and the required investment in equipment by 30% compared to traditional methods.

The initial planned capacity for the factory is 1.25 GWh annually, with a production speed of 20 meters per minute. If you were wondering - a single GWh is enough to power tens of thousands of EVs. The company hopes to expand the site in the coming years to include a 5 GWh R&D center and a more integrated production line.

Anwa has laid out an ambitious roadmap that extends beyond these first samples. A second-generation battery, with an even higher energy density of 400 Wh/kg, has already entered trial production. The company is targeting 2027 for the volume assembly of its third-generation batteries, with a promised energy of 500 Wh/kg.

If Anwa manages to achieve that, it could dramatically alter the performance and cost of electric vehicles. While no specific models have been confirmed to get these batteries, Chery's own Exeed Exlantix ET electric crossover was previously spotted with "All-solid-state battery" branding, hinting at where this technology might first appear.

This milestone is very important, but as always, a dose of reality is a good idea. The move from engineering samples to millions of cars on global roads is a long and challenging journey filled with manufacturing problems and high costs. The electric car industry is littered with bold battery promises that have yet to materialize.

All that aside, the production of physical, testable batteries from a dedicated factory, backed by a major automaker like Chery, suggests this specific development carries more weight than a simple press release. It's a clear sign that the theoretical advantages of solid-state batteries are slowly but surely inching toward the showroom floor.

Reader comments

- Brendan63

- 9Br

he fact that Anwa's production line is claimed to be more energy-efficient is all well and good, but let's not forget that scaling up production and ensuring quality control are major challenges in the automotive industry.

- Anonymous

- kmq

I want a full PHEV with a solid-state battery. This means full-regen of course. German mild-hybrids -- not so much.

Facebook

Twitter

Instagram

RSS

Settings

Log in I forgot my password Sign up