China’s GAC Group starts solid-state battery mass production

China has reached a major milestone in the race for better batteries for electric cars. The country's state media confirmed that the GAC Group has finished building the nation's first production line for large, high-capacity all-solid-state batteries.

Right now, this factory is only making small batches of vehicle-grade cells, but the numbers attached to this new technology are attracting attention across the global automotive industry. These new batteries promise to change what people expect from modern EVs. According to the company, cars that currently travel 311 miles on a single charge could soon travel more than 620 miles.

Traditional lithium-ion batteries, the kind used in today's EVs, rely on liquid materials called electrolytes to move energy. The new solid-state battery replaces that liquid with a solid material. This simple switch brings huge improvements in safety and stability, which is especially important for the powerful batteries needed to run electric cars. The solid material can handle much more heat - reportedly up to 400 degrees Celsius - compared to the approximately 200 degrees that conventional batteries tolerate.

The GAC Group is currently testing cells with a capacity of over 60 Ah. A 60 Ah cell can power a device drawing 60 amperes for one full hour. Having a higher Ah number for each individual cell means the entire battery pack holds more energy, which translates directly into longer driving range for electric cars.

GAC Group's research director, Qi Hongzhong, announced that the energy density of these new cells is almost double that of current conventional batteries. This density jump is also visible in the areal capacity, which is the amount of energy stored on a specific area of the battery. The GAC Group's solid-state battery achieves up to 7.7 mAh/cm², a big increase from the less than 5 mAh/cm² found in older, "wet" lithium-ion batteries.

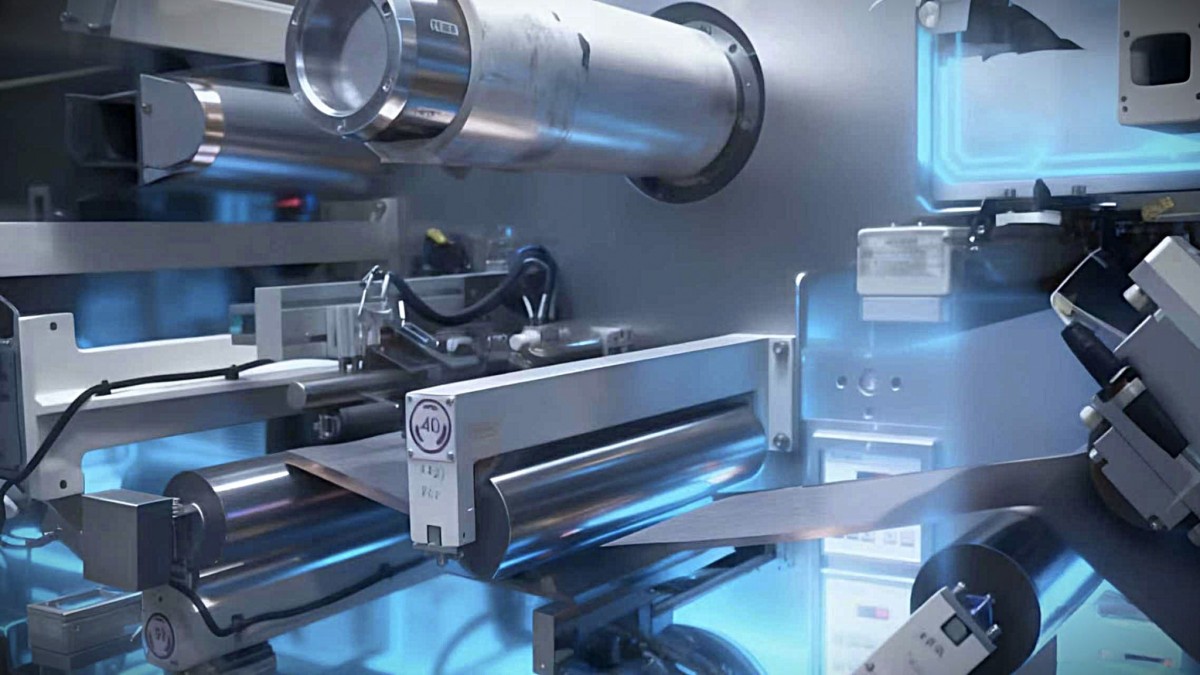

Building these next-generation EV batteries requires advanced production methods. The GAC Group developed an innovative "dry" anode process. This streamlined technique combines several steps - slurry mixing, coating, and rolling - into one single, efficient action. Industry observers note that this approach improves how quickly the batteries can be manufactured while also cutting down on the energy required to make them.

Any process that improves efficiency and reduces production cost is a major win for the mainstream adoption of electric cars. The new production line is China's first to show industrial capability for making these large-format solid-state battery cells, which is a key technical achievement for the nation's automotive goals.

The bad news for us is that the solid-state battery technology is not hitting dealership floors next week. The GAC Group plans to start small-batch vehicle integration tests in 2026. This means engineers will put the new batteries into actual test vehicles to check their performance and safety on the road.

After those vital tests, the company expects to begin gradually ramping up to full mass production, a process planned to start sometime between 2027 and 2030. This is a huge technical victory for the GAC Group, but turning the technology into a reliable, cost-effective product for all electric cars will be the next major challenge.

Commercializing a completely new battery type means solving major logistical puzzles. The successful scale-up of this technology will depend heavily on securing enough investment and ensuring a reliable supply chain for the special solid electrolyte materials. The company must fully validate the long-term performance and safety of these new EV batteries over years of use in different environments.

Globally, manufacturers of electric cars are racing to perfect solid-state technology, but commercial production is still limited everywhere. The GAC Group now holds a key position in this race, but the final impact on the price and availability of EVs will be determined by how fast they can lower the cost of making these advanced cells.

The solid-state batteries totally rewrite the EV user experience. By nearly doubling the range, the need for frequent stops largely disappears. A high-capacity cell, like the one being produced by GAC, provides the fundamental power block for this shift. With this kind of range, a typical driver might only need to charge their EV once or twice a month, making the daily routine for an electric car far more convenient than even a gas-powered vehicle.

Source (Chinese)

Facebook

Twitter

Instagram

RSS

Settings

Log in I forgot my password Sign up