Porsche shows how AI helped build the new electric Cayenne

Developing a new vehicle is a long and expensive process. Carmakers traditionally build dozens, sometimes hundreds, of early prototypes to test everything from door handles to engine performance. It's a method that costs millions of dollars and can take years.

For its upcoming Cayenne Electric, Porsche decided there had to be a better way. By leaning heavily on artificial intelligence and virtual simulations, the German automaker managed to slash development time and skip building over 100 physical test cars.

This new electric SUV represents a big change in how Porsche designs its electric cars. Instead of building physical models early in the process, engineers created a "digital twin" - a highly detailed virtual version of the Cayenne Electric. This allowed them to conduct extensive testing inside a computer before a single piece of metal was ever shaped.

"This project was the first in which we moved directly from digital whole-vehicle testing to pre-series production," explained Dr. Michael Steiner, a key member of Porsche's research and development team. This digital-first approach cut the vehicle's development time by no less than 20 percent.

But these weren't simple video game simulations. Engineers put the virtual Cayenne Electric through a combination of tests that mirrored real-world conditions. The digital SUV completed laps on a virtual Nürburgring racetrack, navigated simulated city traffic, and completed punishing endurance runs.

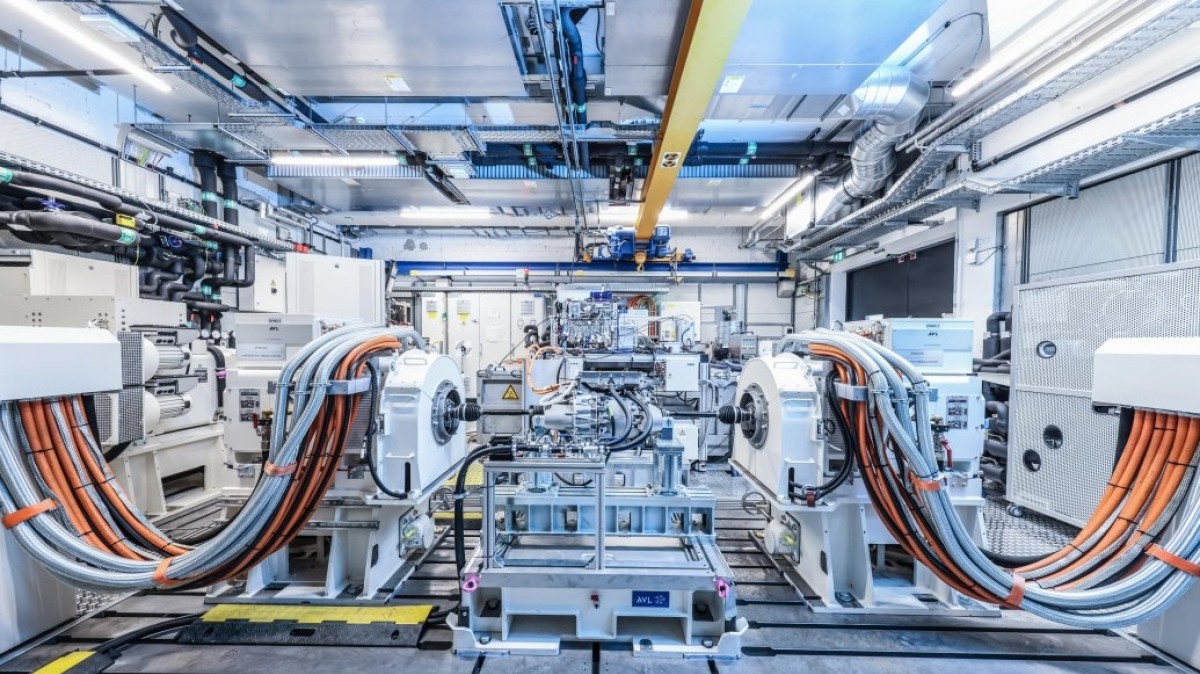

Inside the computer, engineers could instantly swap out virtual components like tires, shock absorbers, and suspension bushings to find the perfect combination for performance and comfort. A new, advanced test bench was also developed to put the electric motors, battery systems, and charging technology through their paces. Engineer Marcus Junige noted the system is so precise, "we can even display different asphalt surfaces or tire slip," ensuring the electric powertrain could handle the immense stress of delivering instant power on demand.

The main benefit of this virtual development is efficiency. Porsche estimates that this process eliminated the need to build around 120 early-stage physical prototypes. These cars are handmade, incredibly expensive, and time-consuming to produce. By keeping the initial testing in the digital realm, the company saved a big chunk of money and resources.

This speed is crucial for established automakers like Porsche, who face fierce competition from new EV companies, especially from China, that are known for bringing new electric cars to market very quickly. Using AI and simulation helps level the playing field.

Of course, a computer can't tell you everything. While virtual testing handled the initial heavy lifting, Porsche didn't abandon real-world validation entirely. Once the design was finalized digitally, the company built a fleet of pre-series prototypes for physical testing.

These real-world versions of the Cayenne Electric were then put through some of the planet's most extreme conditions. They were driven in the scorching 122°F heat of Death Valley, California, and the freezing -31°F cold of Scandinavia, with each test vehicle covered approximately 93,200 miles.

The resulting Porsche Cayenne Electric is expected to go on sale in early 2026. It is built on a stretched version of the 800-volt Premium Platform Electric (PPE) architecture, the same foundation used for the new Macan Electric. It will have a large 108 kWh battery, targeting a range of around 373 miles on the European WLTP cycle.

The SUV will also have Porsche's Active Ride suspension for superior handling, and it will even be able to produce V8-like sounds in its sportiest driving mode. Three versions are anticipated, starting with a base model producing 400 PS, a more powerful 'S' trim with 600 PS, and a top-tier 'Turbo' model delivering over 800 PS.

Reader comments

- Anonymous

- 39y

So where does the AI come in? creating a digital model and running simulations does not require "AI". No explanation of machine learning? nor is there use of llm mentioned? what AI?

Facebook

Twitter

Instagram

RSS

Settings

Log in I forgot my password Sign up